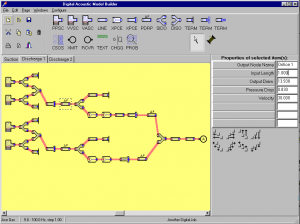

A section of 6 full-time technicians was simulating compressor-piping interaction using a huge number of electronic components (capacitors, inductors, etc.) to predict where acoustical resonances could cause structural failures. This labor-intensive technique took a team of two people two weeks to assemble the model, run the initial simulation, revise the model, run the revised simulations, disassemble the model, and manually prepare a report.

By digitizing the entire process, it now takes a single person two days to complete a job with multiple revisions, and generate a finished report.

The Modeler itself is not shown, as it has no screen interface. It executes on a cluster of high-speed computers and returns results to the operator that submitted the job.