Operators of large industrial engines are able to measure the deflection of a single segment of a crankshaft (known as a web) to determine that web’s stress on the shaft. Unfortunately the operators that contracted us for this program were unable to assess the cumulative stress of multiple webs on a single shaft.

Based on a unifying equation, our program allows users to compile multiple web deflection measurements into a complete and easy to understand picture of the crank shaft’s shape and motion.

Using this program has helped many operators prevent crankshaft breakage (a costly occurrence) by focusing their maintenance dollars on the units showing the worst distortion.

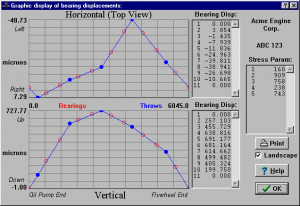

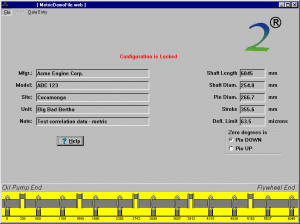

MainThe main window shows a diagram that the user can manipulate to indicate throw and bearing positions, and miscellaneous input parameters.

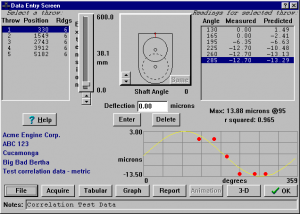

For each throw on the crankshaft, the user enters readings of web deflection and the program calculates the path taken by the web as it rotates.